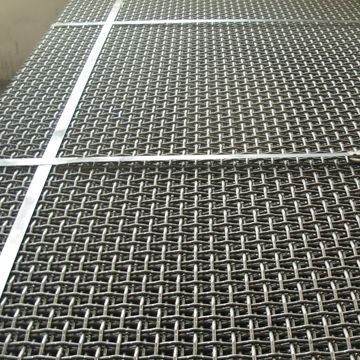

Quarry Screen

quarry screen mainly used for all kinds of sand,rock, stone, coal and other material screening and grading.

topnetting wire screens was made from high tensile,high carbon steel and stainless steel,wear and abrasion resistant,long screening time.

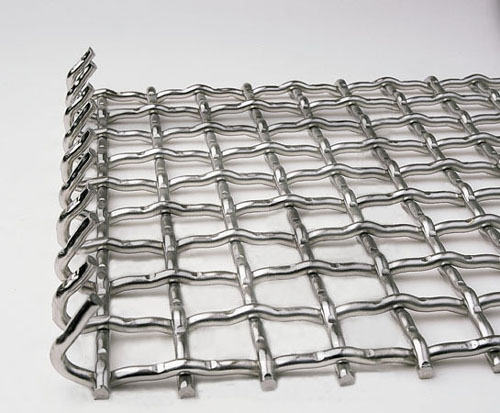

Weaving : plain weave,double crimped ,lock crimped,flat top crimped.

Mesh style: square,rectangular,diamond,triangle,long lot etc

Wire diameter: 0.71mm - 12.5mm

Aperture 1mm - 100mm

Supplied professional C,V hook process and surface treatment.

quarry screen mainly used for all kinds of sand,rock, stone, coal and other material screening and grading.

topnetting wire screens was made from high tensile,high carbon steel and stainless steel,wear and abrasion resistant,long screening time.

Weaving : plain weave,double crimped ,lock crimped,flat top crimped.

Mesh style: square,rectangular,diamond,triangle,long lot etc

Wire diameter: 0.71mm - 12.5mm

Aperture 1mm - 100mm

Supplied professional C,V hook process and surface treatment.

Features Of Screen Mesh For Quarry:

1, Product name: Screen Mesh For Quarry

2, Hardness: HB 220~240

3, Production capability: More than45000tons/year

4, Material & Standard: High manganese steel, Mn14Cr2, Mn18Cr2, Mn24Cr3, Cr20, Cr24up, Carbon steel, Cr-Mo alloy steel; Standards as following: JIS, DIN, ASTM, BS

5, Molding processing: Lost wax process or waterglass sand

6, Melting facilities: Medium frequency electric induction furnace/electric arc furnace.

7, Casting Inspection: Direct-reading spectrum instrument, metallographic analysis, ultrasonic inspection, magnetic particle inspection, mechanical properties inspection.

8, Heat treatment facilities: Special heating electric furnaces, special water pools etc. Special quenching equipments.

9, Surface treatment: Shot blast cleaning.

10, Industry categories: Mining machinery, construction machinery, mineral processing, structural shredder parts, and others.

|

|

|

|

|

|

|

Aperture (mm) |

Nominal Wire Dia (mm) |

Approx. Free screening area% |

Aperture (mm) |

Nominal Wire Dia (mm) |

Approx. Free screening area% |

Aperture (mm) |

Nominal Wire Dia (mm) |

Approx. Free screening area% |

|

2 |

1.25 |

38 |

16 |

4 |

64 |

40 |

5.6 |

77 |

|

2.5 |

1.25 |

44 |

|

5 |

58 |

|

6.3 |

75 |

|

3.15 |

1.25 |

51 |

|

5.6 |

55 |

|

8 |

69 |

|

4 |

1.6 |

44 |

20 |

5 |

64 |

|

10 |

64 |

|

1.25 |

58 |

|

5.6 |

61 |

45 |

5.6 |

79 |

|

|

1.6 |

51 |

|

6.3 |

58 |

|

6.3 |

77 |

|

|

5 |

1.6 |

57 |

22.4 |

5 |

66 |

|

8 |

72 |

|

2 |

51 |

|

6.3 |

60 |

|

10 |

67 |

|

|

2.5 |

45 |

25 |

5 |

69 |

50 |

6.3 |

79 |

|

|

6.3 |

2 |

58 |

|

6.3 |

64 |

|

12 |

65 |

|

2.5 |

51 |

|

8 |

57 |

56 |

6.3 |

81 |

|

|

3.15 |

45 |

28 |

5.6 |

69 |

|

8 |

77 |

|

|

8 |

2 |

64 |

|

6.3 |

67 |

|

10 |

72 |

|

2.5 |

58 |

|

8 |

61 |

|

12 |

68 |

|

|

3.15 |

52 |

31.5 |

5.6 |

72 |

63 |

6.3 |

83 |

|

|

10 |

2.5 |

64 |

|

6.3 |

70 |

|

8 |

79 |

|

3.15 |

58 |

|

8 |

64 |

|

10 |

74 |

|

|

4 |

51 |

|

10 |

58 |

|

12 |

71 |

|

|

12.5 |

3.15 |

64 |

36 |

5.6 |

75 |

80 |

8 |

83 |

|

4 |

57 |

|

6.3 |

72 |

|

10 |

79 |

|

|

5 |

51 |

|

8 |

67 |

|

12 |

76 |

|

|

14 |

3.15 |

67 |

|

10 |

61 |

100 |

8 |

86 |

|

4 |

61 |

|

|

|

|

10 |

83 |

|

|

5 |

54 |

|

|

|

|

12 |

80 |

|

|

Custom Size |

||||||||